Additive Manufacturing (also known as 3-D printing) requires carefully engineered compounds in order to make high-quality end products. Authors Farzadfar et al. have determined a process for manufacturing a bimodal powder that has both the desired particle density and still flows freely.

Farzadfar and his team at Cornell University set out to determine the best powder combination to serve as the material for the laser powder bed fusion (L-PBF) process, commonly used in additive manufacturing. The performance of the powder used in manufacturing greatly affects the properties of the final 3-D printed object.

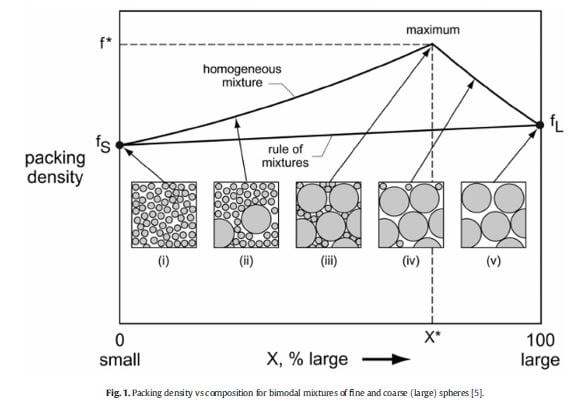

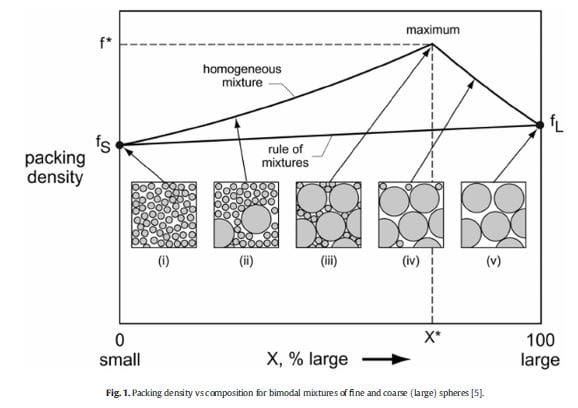

Other groups have tested monomodal powders (powders made up of particles all within the same size range) with narrower and broader particle size distribution (PSD), and found pros and cons to the various sizes tested. The approach of Farzadfar et al. was to mix coarse and fine powders, creating a bimodal powder, where the fine particles can fill the interstitial voids between the large particles. They determined that a bimodal powder with a high level of performance can be created by taking a typical L-PBF coarse powder sized 26.5-50.5 µm, and adding a fine powder sized 6.2-16.9 µm.

In order to determine the performance of the powder, they analyzed its properties from particle count and morphology, to bulk powder performance during manufacturing, to the final qualities of the printed material.

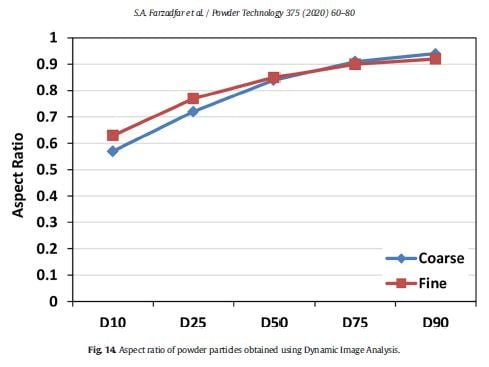

One aspect of the particle morphology that determines the performance of the powder is the particle aspect ratio. FlowCam was used to analyze the aspect ratio of all of the particles in the powder samples and was crucial to the success of this study, as it provided detailed morphological data (including aspect ratio and circularity measurements) based on digital images. Traditional particle analysis methods only provide size and count of particles and would not have been able to assess the shape of the powder particles.

Figure 14 below shows that the particles in both fine and coarse powders had aspect ratios that approached 1.0 (a perfect sphere) as the particle diameters increased.

The sample parts printed using the new bimodal powder showed higher strength, lower ductility (stretchability), and less anisotropic behavior (property variability depending on orientation) than samples printed using a monomodal powder. The parts were also able to be printed 10% faster.

Read the full paper here to learn more about Farzadfar et al.'s methodology:

Impact of IN718 bimodal powder size distribution on the performance and productivity of laser powder bed fusion additive manufacturing process

Published in Powder Technology, Volume 375, 20 September 2020, Pages 60-80

Seyed Amir Farzadfar, Martin J. Murtagh, Navin Venugopal