Superabrasives, such as micronized diamonds and cubic boron nitride (CBN), are used extensively in applications for cutting, grinding, and drilling hard materials. The effectiveness of a particular superabrasive material in a given application is largely determined by both particle size and particle shape.

A lapping compound is one example where superabrasive particles like micronized diamonds are in a liquid or paste transport medium. This compound is used to sharpen or grind metal surfaces. Quality control efforts for the production of these diamonds revolve around ensuring uniformity and shape, as the most effective particles are ones with smooth and rounded edges. Particles with sharp points or edges are more susceptible to breakage.

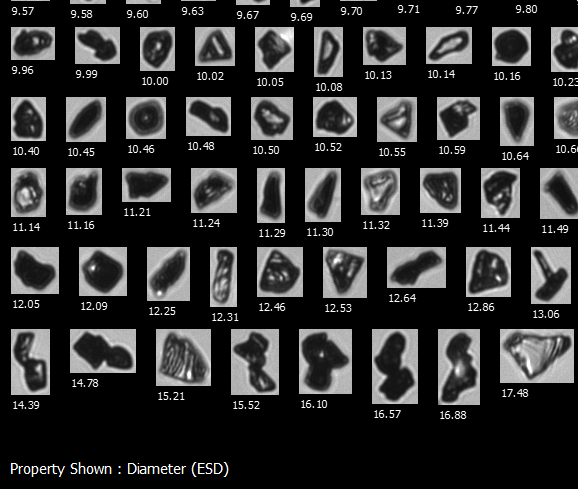

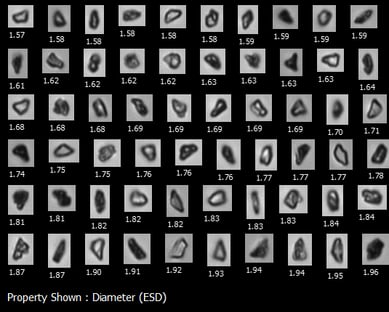

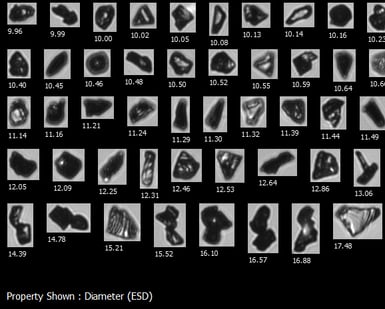

Above images: Left, 40X magnification on FlowCam Nano, mixed diamond powder, particle property shown is Diameter ESD.

Right, 20X magnification on FlowCam 8000 mixed diamond powder particles

This FlowCam was used to analyze their diamond powder to compare the morphological properties of their different lots. Using our VisualSpreadsheet software, we could take thousands of FlowCam images like the ones shown here and show valuable morphological data for their lots. FlowCam confirmed what the customer expected: lots that behaved similarly had similar morphological characteristics, and lots that behaved differently had very different morphological characteristics.

Particle analyzers can be used to determine the size, distribution, and concentration of materials. However, uniformity of shape analysis requires particle morphology. FlowCam offers imaging particle analysis that provides digital images of each particle in a sample. Morphological filters can be applied to sort by different particle properties, such as circularity or aspect ratio. Some manufacturers require at least 95% of the particles meet uniformity standards around circularity or aspect ratio.

FlowCam can image and characterize thousands of particles per minute - making it straightforward to determine if a given batch of superabrasives meets the desired morphological specifications.

Interested in learning more about how FlowCam can simplify and speed your particle characterization?