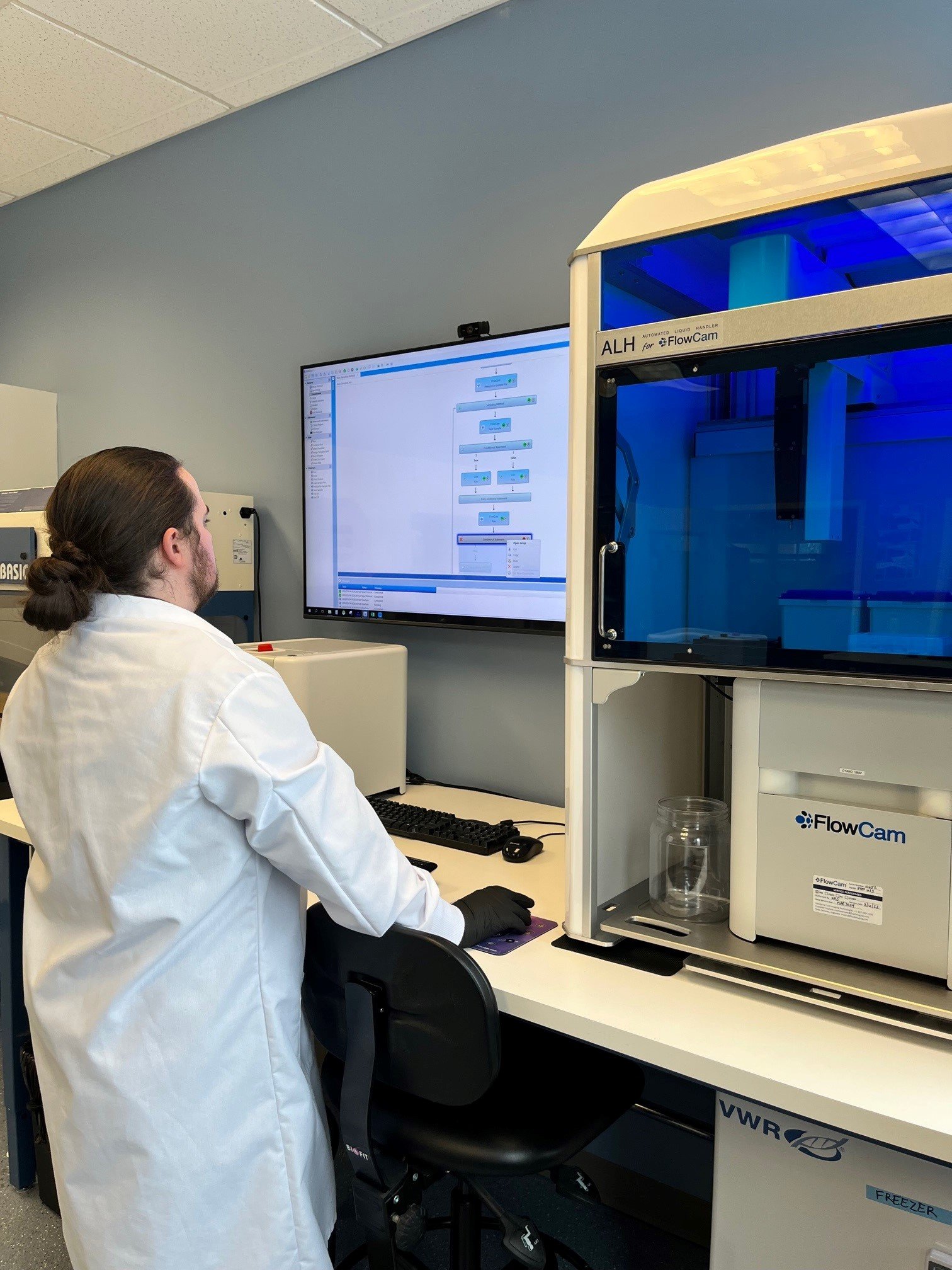

Automated Liquid Handling to Improve Your Particle Analysis Workflow

In modern laboratories, automation is no longer a luxury—it’s a necessity. ALH for FlowCam™ empowers scientists with a high-throughput, user-friendly solution to integrate flow imaging microscopy into their workflow more efficiently and consistently. With customizable hardware and software, ALH for FlowCam adapts seamlessly to your lab’s specific needs, improving reproducibility and saving valuable time.

1. Why Add Automation to Your FlowCam System?

Automation reduces hands-on time and minimizes human error, enhancing both productivity and data quality. ALH for FlowCam enables unattended operation, freeing up analysts to focus on more complex tasks such as experimental design and data interpretation.

By eliminating the variability introduced by manual sample preparation and loading, ALH ensures more consistent, reproducible results. Its intuitive software supports users of all experience levels, from simple push-button workflows to fully customized analysis protocols.

2. How Many Samples Can ALH for FlowCam Handle?

Flexibility is built into the design. The system’s user-configurable deck supports up to 10 positions for well plates, reservoirs, and tip boxes. This allows you to process as many as 384 samples in a single run, using:

- Four 96-well plates

- Four tip boxes for sample handling

- One tip box for cleaning/rinsing

- One reagent reservoir

Whether you're running a few samples or hundreds, the ALH system scales to meet your throughput requirements.

3. How Can I Reduce the Amount of Tip Waste Generated by the System?

Pipette tips are a costly and often overlooked source of laboratory waste, and it is often not necessary to use a fresh pipette tip for every step in an analysis protocol. The ALH system allows you to reuse tips for specific tasks, such as cleaning and rinsing, without compromising data integrity. Tips can be returned to their original positions for later use, reducing overall waste and saving on consumables.

4. Am I Limited to the Plate Types Currently Listed by the Software?

Do you need to analyze samples from non-standard containers, or do you wish to avoid additional transfer steps? No problem. ALH for FlowCam is compatible with a wide variety of labware, including:

- 8-, 24-, 96-, 384-well plates (both shallow and deep-well)

- Any standard SLAS or SBS footprint plate (just enter the dimensions into the ALH software interface)

- Custom-made containers (available upon request)

For additional information or assistance with this procedure, contact support@fluidimaging.com.

5. Are There Additional Features That Will Allow Me to Optimize the ALH for FlowCam System for My Application?

5. Are There Additional Features That Will Allow Me to Optimize the ALH for FlowCam System for My Application?

Whether you're running routine assays or complex workflows, ALH for FlowCam adapts to your needs, offering both built-in routines and a fully programmable interface depending on your analysis goals and expertise level.

Key features include:

- Adjustable sample height and liquid level detection

- Programmable cleaning and rinsing protocols

- On-deck accessories for sample heating, cooling, or shaking

- Built-in sample dilution capabilities

- Conditional logic to modify protocol steps based on particle count, sample ID, or other criteria

These features provide unparalleled control, making it easier to tailor the system to your specific research or QA/QC application.

Ready to Automate Your FlowCam System?

To learn how ALH for FlowCam can help your lab increase efficiency, enhance reproducibility, and reduce operational costs, download our white paper, "5 Key Benefits of Automating Flow Imaging Microscopy" or visit our ALH for FlowCam product page to request a quote.

Download: 5 Key Benefits of Automating Flow Imaging Microscopy