Biopharma

Identify the concentration, size, and types of subvisible and submicron particles present in biopharmaceutical formulations, including protein, cell, and gene therapies with flow imaging microscopy as recommended by USP <1788>.

Gain insight into the sources of particles in biological drug products and optimize formulations and manufacturing processes to minimize and control particle formation and ensure that USP <787> and <788> particle requirements are met.

Helpful Resources

Protein Therapeutics

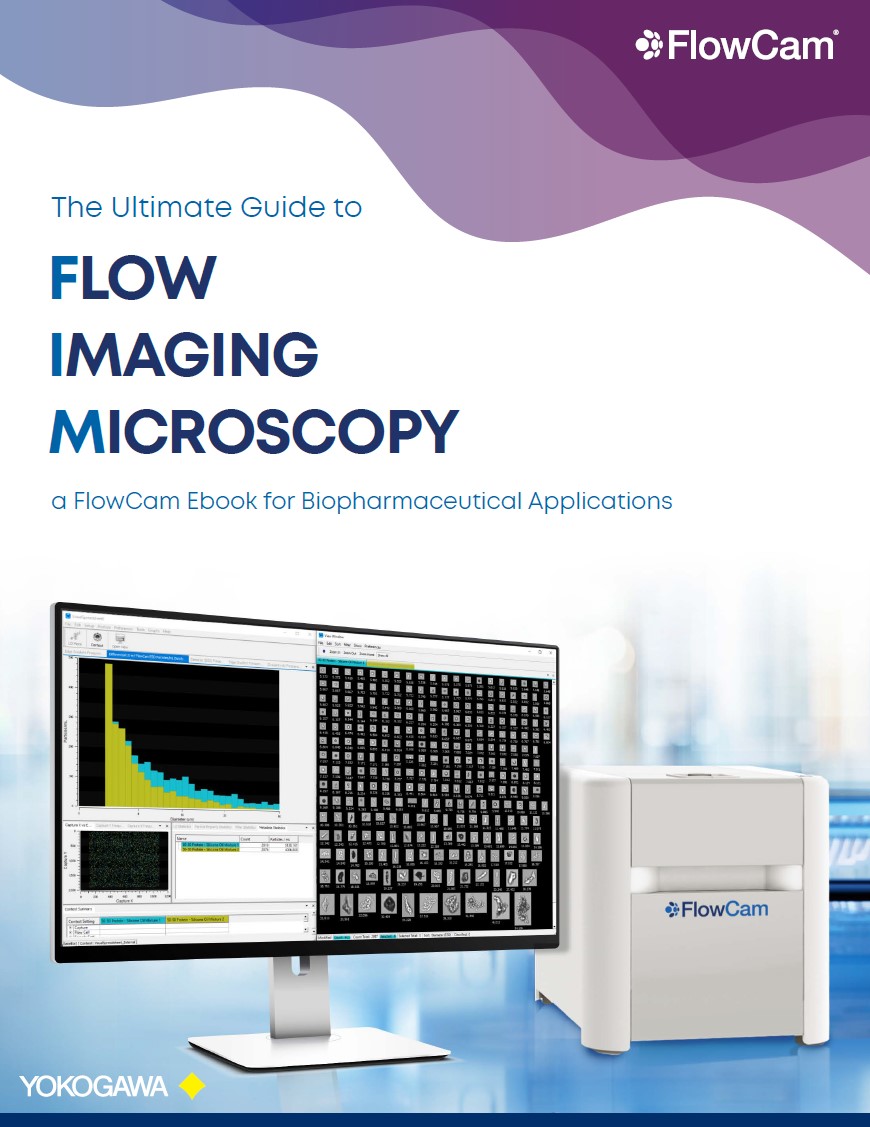

The Ultimate Guide to Flow Imaging Microscopy for Biotherapeutics

Protein Therapeutics

FlowCam Biopharma Applications Brochure

Protein Therapeutics

FlowCam Innovations for Biopharma

Need Supplies?

Find supplies and spare parts for your FlowCam instrument or ask for a quote.

Need Help?

Get technical support and application help. Request training or preventative maintenance.

Need Information?

Check out our knowledge base including white papers, application notes, technical notes, and videos.